The new H1/AS1’s schedule method aims to reduce the energy needed to heat and cool buildings by approximately 40%. To do so, the minimum R-Value of the building envelope needs to increase significantly. Although these new minimums will create more thermally efficient buildings, they will increase roofing costs significantly. This will restrict design with deeper ceiling cavities required for cold roofs, and higher parapets to obscure thicker insulation build-ups for warm roofs.

… Introducing Viking WarmSpan2

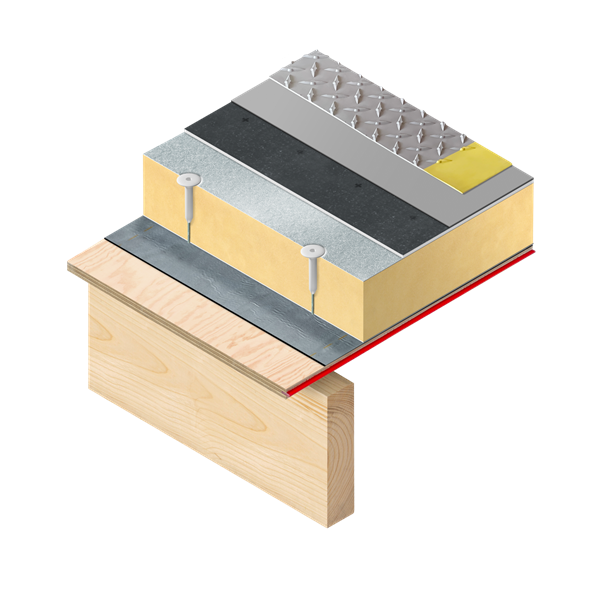

Viking’s WarmSpan2 system is a fully-compliant, engineered warm roof solution that is the result of having analysed every possible component and installation method, to arrive at the most cost-effective; design-flexible; compliant; membrane warm roof assembly – that meets H1 (5th edition).